Our food transfer lines can be equipped with pigging (scraping) and cleaning-in-place (CIP) cleaning systems..

Our food transfer lines can be equipped with pigging (scraping) and cleaning-in-place (CIP) cleaning systems..

Pigging (scraping) principle:

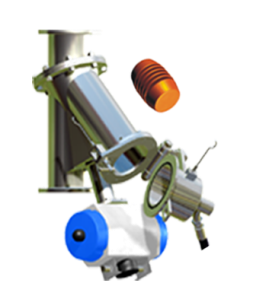

Pig Station showing the pig outside and the hinged housing where the pig is installed prior to line cleaning

The entire pigging technology is controlled by a PLC that takes into account the detection and speed of the pig. The electro pneumatic valves are housed in a stainless-steel box. The method of pushing the pig through the transfer line can be achieved by compressed air or water under pressure.

The DIVERTER VALVE is used because it is designed to receive a secure can have a PIG STATION attached allowing for full product flow generally through the straight section of the valve with the Pig Station mounted on the side port. This fully enclosed system keeps the operators and the product safe.

The entire pigging technology is controlled by a PLC that takes into account the detection and speed of the pig. The electro pneumatic valves are housed in a stainless-steel box. The method of pushing the pig through the transfer line can be achieved by compressed air or water under pressure.

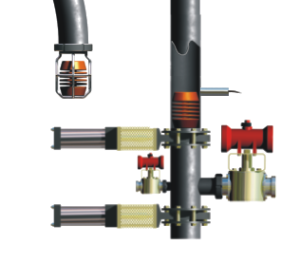

EGRETIER Pig stop valve

The ‘propellant’ (regulated compressed air or water) In the case of shooting, a defined amount of compressed air ensures that the pig starts from its PIG STATION and travels to a designated position where it is stopped. This Pig Stop is a solidly supported pin that is driven pneumatically into the product stream, so it allows product past but stops the full diameter Pig.

After the Pig Stop there is a flap valve (gate valve) that seals off the process transfer line. This allows for ‘propellant’ (compressed air/water) to be delivered to the front of the pig and this pushes the pig back down the line to the pig Station from where it came from. This delivers line cleaning both ways and then CIP cleaning can be used for the final clean of the transfer system for a full hygenic/sanitary clean.

A number of EGRETIER DIVERTER VALVES can be used in a process line if there are multiple discharge points (eg, a number a mixers) and the automation can be programmed to deliver to the selected discharge point as required.

Cleaning in Place (C.I.P.)

This automatic cleaning system can be integrated into our transfer lines or storage silos during their design and equipment or lines do not have to be opened to accommodate this function making for a safe design. The tanks, pipes or other equipped machines are washed using a parallel water circuit. The operator can program different cycles with washing and rinsing products, according to the specifications.

For all specific requests, please contact us, our teams will advise and accompany you to improve your productivity, your development capacity and the quality of your products in complete safety.