This EGRETIER patented pump has been specially designed to handle a large range of different products from grapes to chicken frames/carcasses. The design allows for speedy access for full cleaning and inspection and uses USFDA materials in its construction. Essentially it is fully stainless steel to meet the demands of food manufacturing customers.

This EGRETIER patented pump has been specially designed to handle a large range of different products from grapes to chicken frames/carcasses. The design allows for speedy access for full cleaning and inspection and uses USFDA materials in its construction. Essentially it is fully stainless steel to meet the demands of food manufacturing customers.

EGRETIER bilobe volumetric pump

The pump is coupled to a screw auger (usually from a hopper above) that delivers the product into the pumping chambers as well as driving the pump. The housing is designed such that it accommodates the difference between the continuous feeding nature of the auger screw and the rotating rotor to ‘smooth’ out the resultant flow.

This pump is suitable for a large range of products from delicate fruits to thick meat offals plus fish and crustaceans and direct meat pumping to plate freezers. A very versatile robust pump that is easy to access for maintenance, cleaning and inspection.

Technical data:

Operation of EGRETIER bilobe volumetric pump

Operation of EGRETIER bilobe volumetric pump

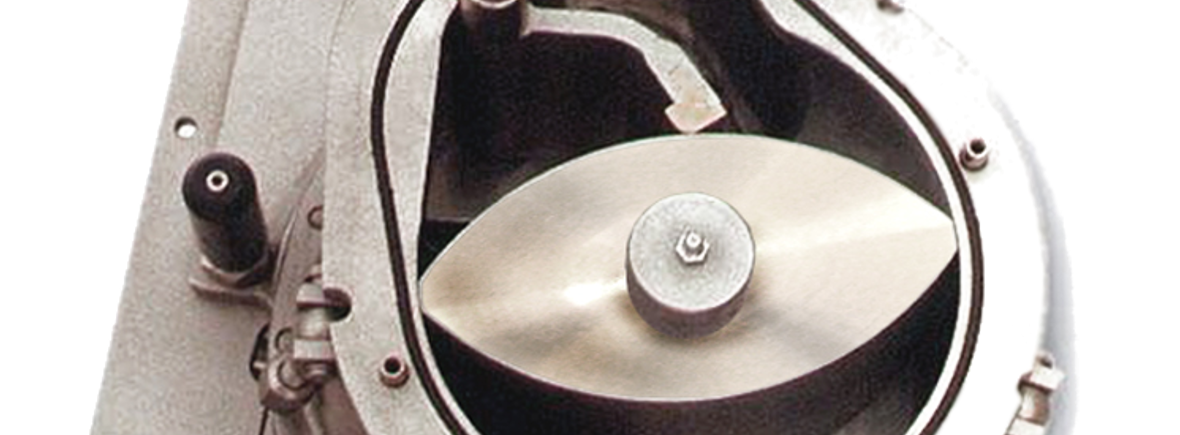

- Removable flap

- External flange with quick disassembly

- Rolling bearing

- Treated (or not) stainless steel rotor

- Forced feeding by auger screw

Features:

- Volumetric at slow speed from 5 to 50 rpm, with internal pump housing capacity from 0.6 to 20 Liters

- Materials 304L or 316L

- Operating pressure 4/15 bar

- Output diameter from 63 to 200 mm

- Built-in ‘booster screw’ from Ø110 to 350mm

EGRETIER Bilobe volumetric pump opened

EGRETIER Bilobe volumetric pump closed

Table des Dimensions

| Réf. Pump Type |

Ø Feed Screw | Ø outlet pipe (useful) |

Flow in m3/h | Volume/tr | Maxi operating pressure |

| 62 | 110 | 50/63 | 0.3 à 1.8 | 0.62 L | 10 bars |

| 125 | 140 | 63/76 | 0.7 à 3.5 | 1.25 L | 12 bars |

| 250 | 200 | 100/110 | 1.5 à 7.5 | 2.50 L | 15 bars |

| 500 | 250 | 120/125 | 3.0 à 15 | 5 L | 15 bars |

| 660 | 250/300 | 120/125 | 4.0 à 20 | 6.6 L | 15 bars |

| 900 | 300 | 125/150 | 5.5 à 27 | 9 L | 15 bars |

| 1200 | 300 | 125/150 | 7.2 à 36 | 12 L | 15 bars |

| 2000 | 350 | 150/180 | 12 à 36 | 20 L | 15 bars |

For all specific requests, please contact us, our teams will advise and accompany you to improve your productivity, your development capacity and the quality of your products in complete safety.